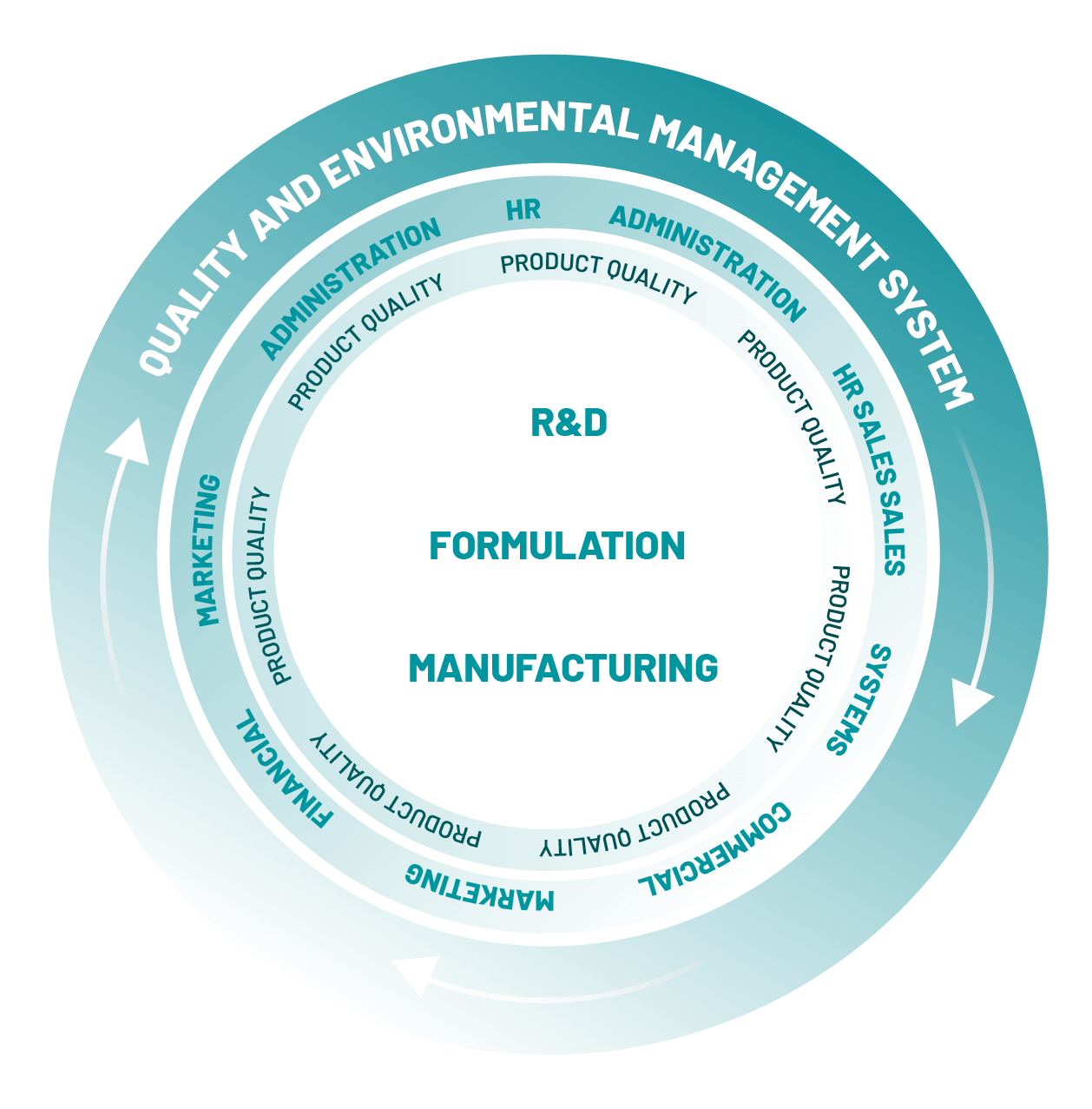

To describe the Servalesa Manufacturing Model, we need to consider the following items:

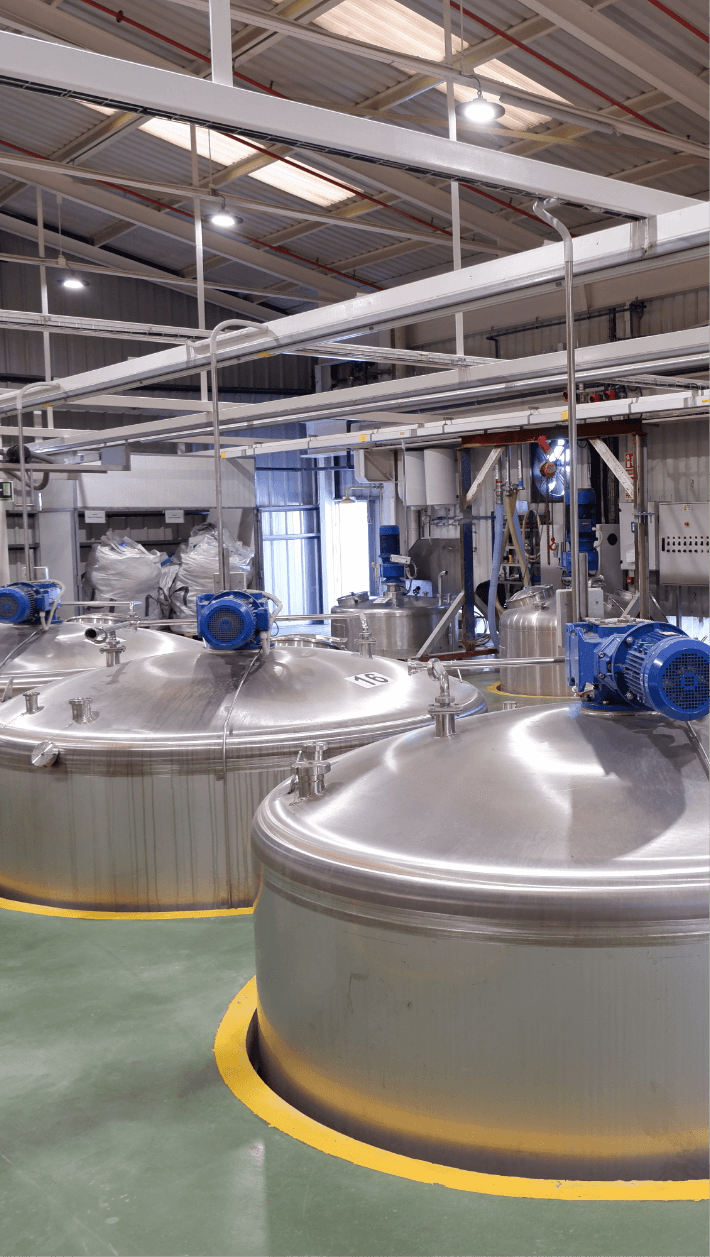

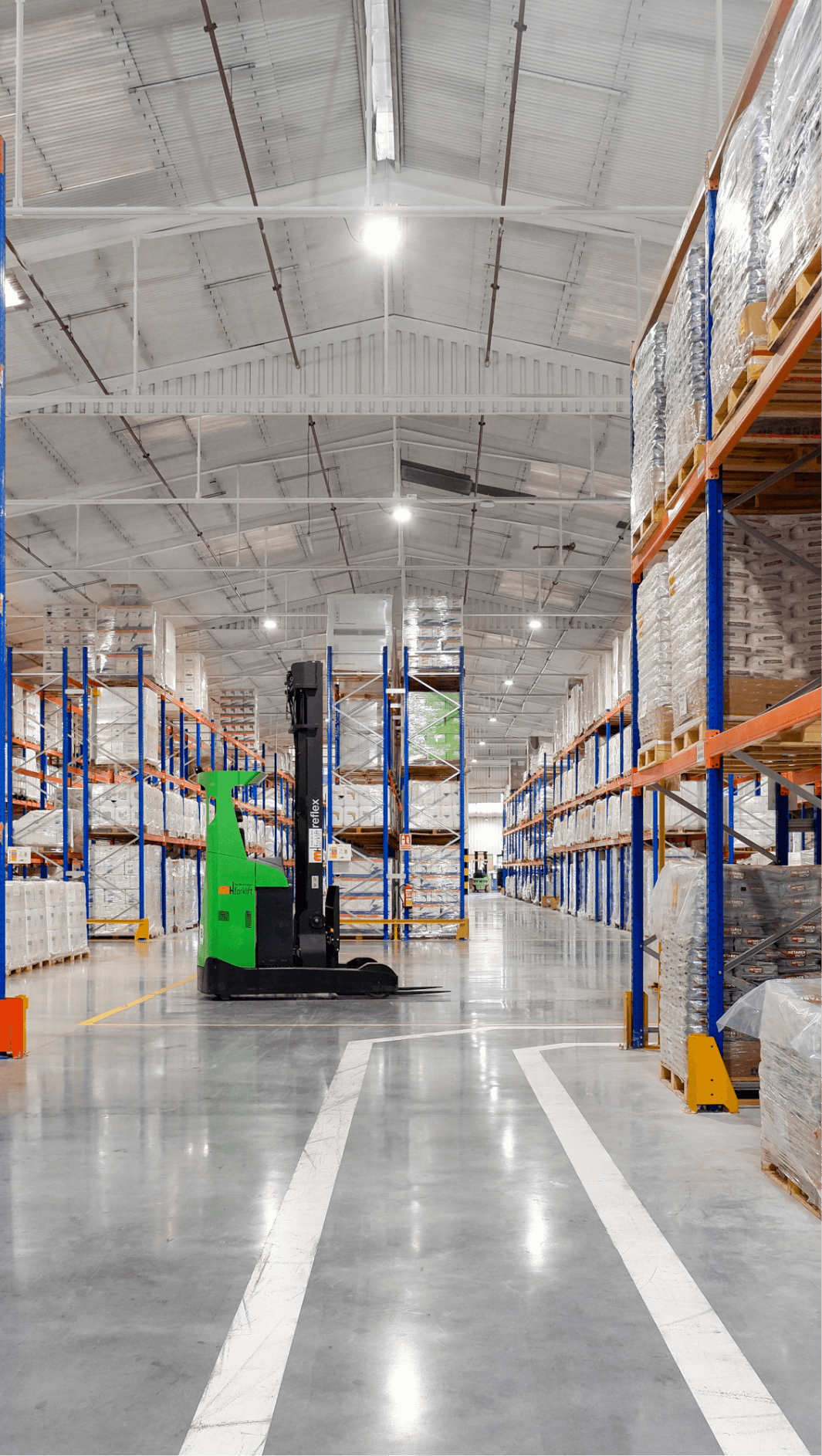

The Quart de Poblet facilities represent the culmination of an industrial project that accumulates more than 40 years of evolution of the production processes. This has enabled us to position ourselves as one of the leading centres for phytosanitary products, fertilisers and biostimulants, able to provide a global response thanks to our technology, facilities and location, in the surroundings of the logistics hub of the port of Valencia.

Our model is characterised by adaptability and flexibility, enabling us to face the challenges and dilemmas of the market in all its key processes: formulations, labelling, packaging, etc.

Rigour and traceability throughout the development of Servalesa products, especially in the formulation processes, where we deal with a high variability of formulations, and precision in each development is key in our manufacturing model. This enables us to keep our production processes and thus our quality standards consistent

Synergy with other departments so we can stay up to date on market trends to meet the real needs of our customers when developing our products

We employ a multidisciplinary team of professionals, where knowledge of chemistry, production, industrial planning and operational support converge. A diverse team, but with one common goal: to continue evolving in the development of our products, for the farming of the future